9 Easy Facts About Water Filtration Filters Shown

Table of ContentsThe smart Trick of Water Filtration Filters That Nobody is Talking AboutThe Definitive Guide to Water Filtration FiltersThings about Water Filtration FiltersWater Filtration Filters for Beginners

A phosphorous compound is included in aid control rust of pipelines. This aids protect against lead and also copper that may be existing in pipes from seeping right into the water. As the water leaves the plant, ammonia is included in change the chlorine to chloramine, a disinfectant that maintains a recurring in the distribution system against bacterial contamination. water filtration filters.All chemicals that are added are certified food quality, secure for usage in foods. Dealt with water is stored in deep below ground tanks as well as likewise moves by gravity to pumping terminals as well as into the distribution system. The distribution system includes 1,960 miles of water pipe ranging in diameter from 4" to 60".

Elimination of taste and also odor compounds from the water.: Softens the water.: Filtration to eliminate small fragments and also sanitation to kill infections as well as bacteria, and ensure an inappropriate setting for infection as well as bacteria development throughout the circulation system (water filtration filters).

The Buzz on Water Filtration Filters

According to the EPA, The Tidy Water Act (CWA) establishes the fundamental structure for controling discharges of contaminants right into the waters of the USA and also controling quality criteria for surface waters. Under the CWA, EPA sets wastewater standards for market. The EPA has actually also created nationwide water top quality requirements referrals for contaminants in surface waters.

Relevant White Papers Select Products Phase 2 Screening Removal of grit by flowing the influent over/through a grit chamber. Fine grit that discovers its method right into the influent requirements to be gotten rid of to avoid the damage of pumps and also devices downstream (or impact water flow). As well small to be screened out, this grit requires to be eliminated from the grit chamber.

Stage Four Aeration Air is pumped right into the oygenation tank/basin to motivate conversion of NH3 to NO3 and also provide oxygen for bacteria to continue to multiply and also grow. As soon as transformed to NO3, the germs remove/strip oxygen molecules from the nitrate particles and also the nitrogen (N) is released as N2 (nitrogen gas).

This begins in the aeration storage tank. The primary feature of the aeration storage tank is to pump oxygen into the storage tank to motivate the malfunction of any type of organic material (and also the growth of the bacteria), as well as make certain there suffices time go now for the natural material to be broken down - water filtration filters.

The Definitive Guide to Water Filtration Filters

This process Your Domain Name is taken care of to use the very best problems for microbial growth. Oxygen gas [O2] levels below 2 ppm will exterminate the germs, decreasing efficiency of the plant. Liquified oxygen monitoring at this stage of the plant is critical. Ammonia as well as nitrate measurements prevail to measure how effective the bacteria are in converting NH3 to N2.

Part of this triggered sludge is returned to the oygenation container to boost the microbial concentration, assistance in propagation, and accelerate the malfunction of organic material. The unwanted is disposed of. The water that streams from the second clarifier has substantially reduced natural product as well as needs to be coming close to expected effluent specs.

With the improved concentration of microorganisms as part of the aeration stage, there is a requirement to check the outgoing effluent for bacteria existence or lack as well as to sanitize the water. This makes certain that more than defined focus of microorganisms are not launched right into the setting. Chlorination is the most typical and cost-effective kind of disinfection yet ozone as well as UV sanitation are additionally boosting in appeal.

Get This Report about Water Filtration Filters

Water is guided from the Head Container to the Claricone clarifier. Water goes into the clarifier at the blending zone located in the bottom of the Claricone. Lime is included in the water in this area where it responds with the calcium and the magnesium in the water to create precipitates.

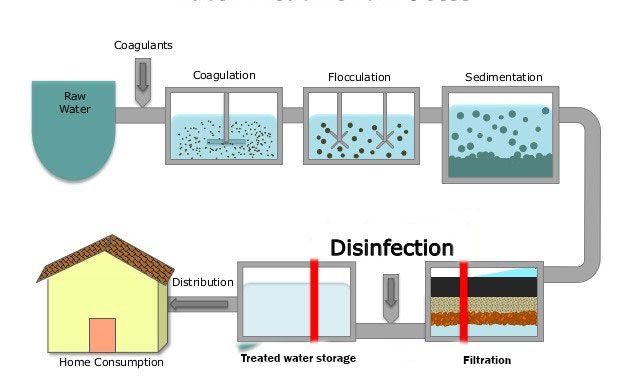

After adequate time, bits comply with each various other and also turn into larger fragments, or, floc, which is prone top article to resolve in water. This procedure of floc formation is called flocculation. To help in the flocculation of particles, an anionic polymer is included in the blending area of the cone. Information of water is completed by the seperation of put on hold solids from water by gravity.

The cleared up water relocations upwards slowly, at some point passing over the effluent weir to the cone outlet as well as on the to filters for more treatment. The water plant includes a solitary phase lime softening procedure to eliminate firmness. Solidity is brought on by the existence of dissolved bivalent as well as polyvalent metal ions, primarily calcium and also magnesium.

This is added both in the clearwell as well as the high solution discharge as water goes into the circulation system. Hydrofluosilicic acid provides the resource of fluoride, which is beneficial in the prevention of dental caries in kids. A fluoride focus of 1. 1-1. 2 mg/l is typically desirable in the plant tap.